Gases for Semiconductor Manufacturing and Fabrication

At INOX Air Products, we deliver an extensive portfolio of ultra-high-purity specialty gases, bulk solutions, as well as onsite generation of gases, underpinned by a robust and reliable supply chain. Our offerings of gases used in semiconductor manufacturing ensure producers benefit from the highest quality standards, precision, and sustainability, supporting a seamless and efficient production process.

INOXAP’S Material & Technology Overview For Semiconductor Fabs

The semiconductor industry is among the most dynamic, complex, and fiercely competitive markets globally. As the sector expands, the need for ultra-pure gases and chemicals intensifies, especially gases used in semiconductor manufacturing. The semiconductor gases supply chain is a complex network of production, distribution, and delivery of specialty semiconductor manufacturing gases, critical to high-quality chip and device manufacturing. Therefore, close collaboration, efficient logistics, and robust safety protocols are essential for a reliable supply of gases for chip manufacturing and electronic gases.

Our Product Offerings

- Silicon Semiconductor

- Compound Semiconductors

- PV

- Mutipurpose

- Others

CVD

Silane

Diborane

Germane

Silicon Tetrafluoride

Ammonia

Phosphine

Dichlorosilane

Disilane

Tungsten Hexafluoride

Propylene

Cleaning & Etching

Nitrogen Trifluoride

Hexafluoro Ethane

Hexafluoro-1,3-butadiene

Tetrafluoromethane

Carbonyl Sulfide

Difluoromethane

Sulfur Hexafluoride

Boron Trichloride

Carbon monoxide

Octafluoro Propane

Octafluorocyclopentene

Trifluoromethane

Pentafluoroethane

Methyl Fluoride

Chlorine

Hydrogen Bromide

Ion Implant

Arsine

Boron Trifluoride

Germanium tetrafluoride

Arsine Mixtures

Boron Trifluoride

Germanium Tetrafluoride

Phosphine

Silicon Tetrafluoride

Hydrogen Selenide

Phosphine Mixtures

Silicon Tetrafluoride

Compound Semiconductors

Arsine

Ammonia

Phosphine

PV

Silane

Diborane

Ammonia

Nitrogen Trifluoride

Phosphine

Germane

Hydrogen Selenide

Sulfur Hexafluoride

Nitrous Oxide

Mutipurpose

Nitrogen

Argon

Carbon Dioxide

Oxygen

Helium

Nitrous Oxide

Others

Nitric Oxide

Deuterium

Helium+Oxygen Mixture Gas

Nitrogen+Hydrogen

Mixture Gas

Hydrogen

Argon+Oxygen Mixture Gas

Argon+Methane Mixture Gas

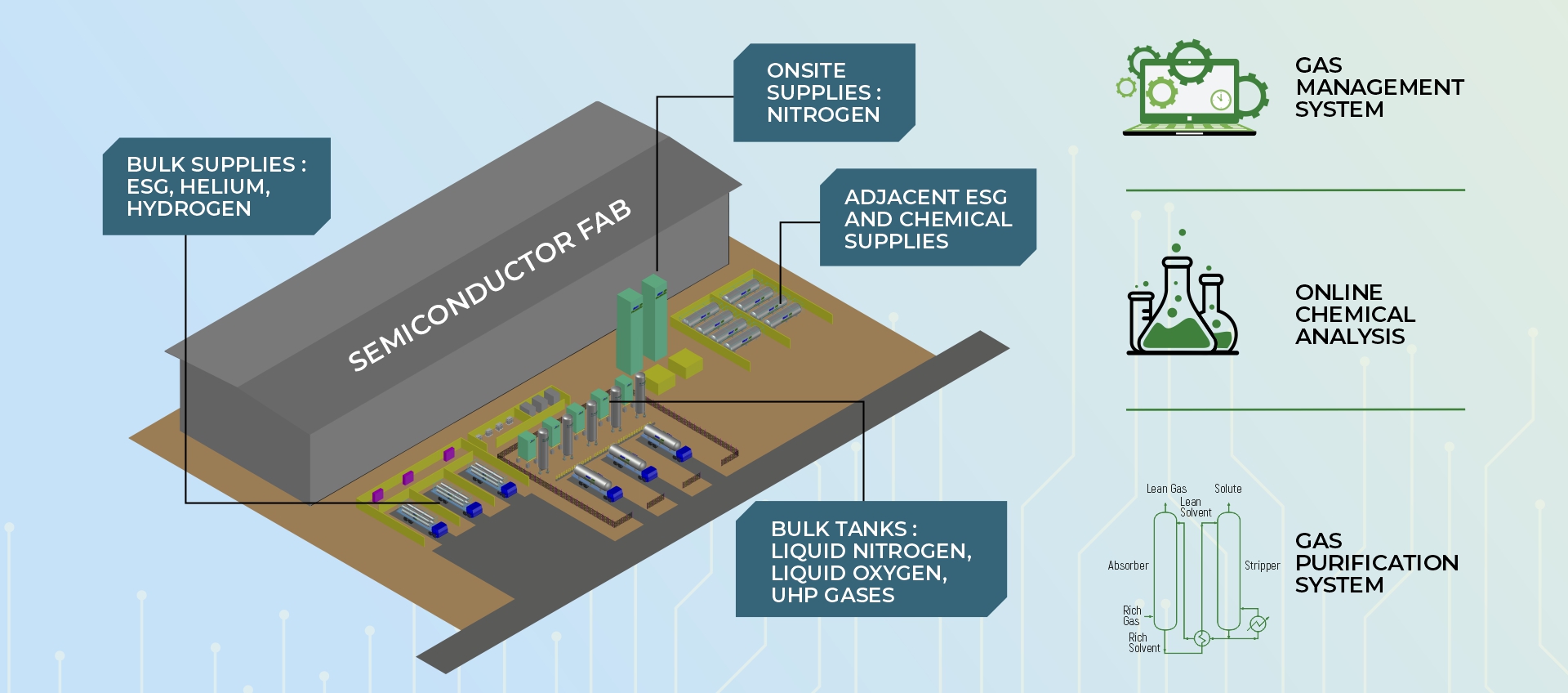

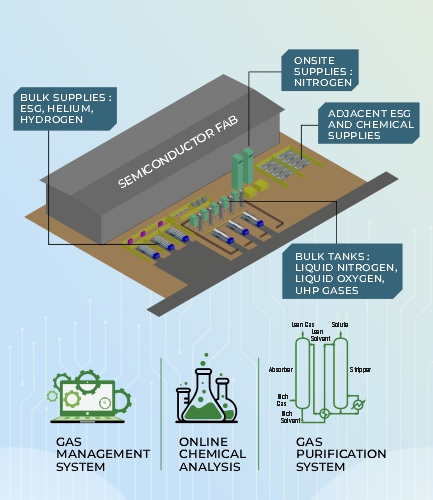

Total Gas Management

Total Gas Management (TGM) involves overseeing the entire lifecycle of speciality and electronic gases, from production and transportation to distribution and consumption. It focuses on optimizing efficiency, safety, and sustainability through processes like monitoring production rates, managing pipelines, ensuring regulatory compliance, and using advanced technologies for real-time monitoring. TGM also includes risk management, demand forecasting, and reducing environmental impact, all aimed at ensuring safe, reliable, and efficient operations of gases for semiconductor manufacturing across the supply chain. Additionally, it ensures precise handling of every gas used in semiconductor applications to maintain product quality and operational safety.

Reliable Bulk Gas Solutions for Semiconductor Manufacturing

Semiconductor manufacturers rely on a secure supply of essential bulk gases, including Nitrogen (N2), Oxygen (O2), Argon (Ar), Hydrogen (H2) and Helium (He). At INOXAP, we provide comprehensive gases for semicon manufacturing, ensuring uninterrupted supply, consistent quality, and optimal purity across production processes. Our expertise includes design and installation services for:

- Bulk storage tanks

- Evaporators

- Purifiers

- Filtration systems

- Ultra-high-purity distribution systems

The numerous benefits of bulk gas solutions include a reliable supply of gases for semicon manufacturing, enhanced manufacturing efficiency, reduced downtime, improved product quality, and customized solutions tailored to unique customer needs.

On-site Gas Generation Solutions for Semiconductor Manufacturing

We offer our customers onsite gas generation solutions since large volumes of high-purity gases, including Nitrogen (N2), Oxygen (O2), Hydrogen (H2) and Compressed Dry Air (CDA) are critical for operations. On-site generation of these gases provides significant benefits for semiconductor manufacturers, ensuring a constant and reliable supply of gases for semiconductor manufacturing, reduced transportation costs, increased production efficiency, enhanced product quality, and customized solutions for unique customer needs. Our systems also guarantee a consistent supply of high-purity gas for semiconductor, minimizing downtime and optimizing production.

A Robust Supply Chain: Delivering On Time With Certainty

We deliver a comprehensive portfolio of ultra-high-purity gases for semiconductors, backed by a robust and reliable supply chain to ensure precision and performance at every stage. Our supply chain relies on ISO Packages, Cylinders, Mixed Gases, Tube Trailers, Bulk Cryogenic Liquid, On Site/Over-The-Fence Gas Solutions and Bulk Special Gases.

Customers We Serve

Semiconductor manufacturers need a reliable and responsive partner with a wide reach and the technical capability to safely supply semiconductor manufacturing gases, ensure the highest quality, manage costs, reduce environmental impact, and drive innovation for the future. At INOX Air Products, we are the leading manufacturer of Industrial gases committed to maintaining a sustainable and scalable value chain for the burgeoning semiconductor industry in India. We have been a supplier of choice for high-purity gases for chip manufacturing to numerous solar cell, semiconductor and electronic industry manufacturers in India, and through our JV partner Air Products, in China, USA, Taiwan, South Korea, Ireland, Israel, Malaysia, and the EU, with over 100 installations in this segment.

For more information, email us at info@inoxap.com or contact your INOX Air Products Sales Coordinator.